Ribbon Blender

Our ribbon blender is a versatile and widely used mixing equipment designed to blend dry or semi-dry materials uniformly, making it an essential tool in various industries that require efficient and consistent mixing of bulk solids.

It consists of a large, horizontal trough-shaped container with a set of inner and outer helical agitators, often referred to as ribbons, that move the materials in opposite directions. The ribbons are shaped like a double helix and are designed to efficiently mix and blend ingredients.

Six models to choose from: 7, 10, 18, 35, 53, 70 cu ft.

Get a quick quote!

Simple, affordable pricing. Free product demos are also available.

Features

- Commonly used in the food, chemical, and Pharma industries for quick mixing of dry granular & powders

- Heavy gauge 304 stainless steel construction with welded end plates

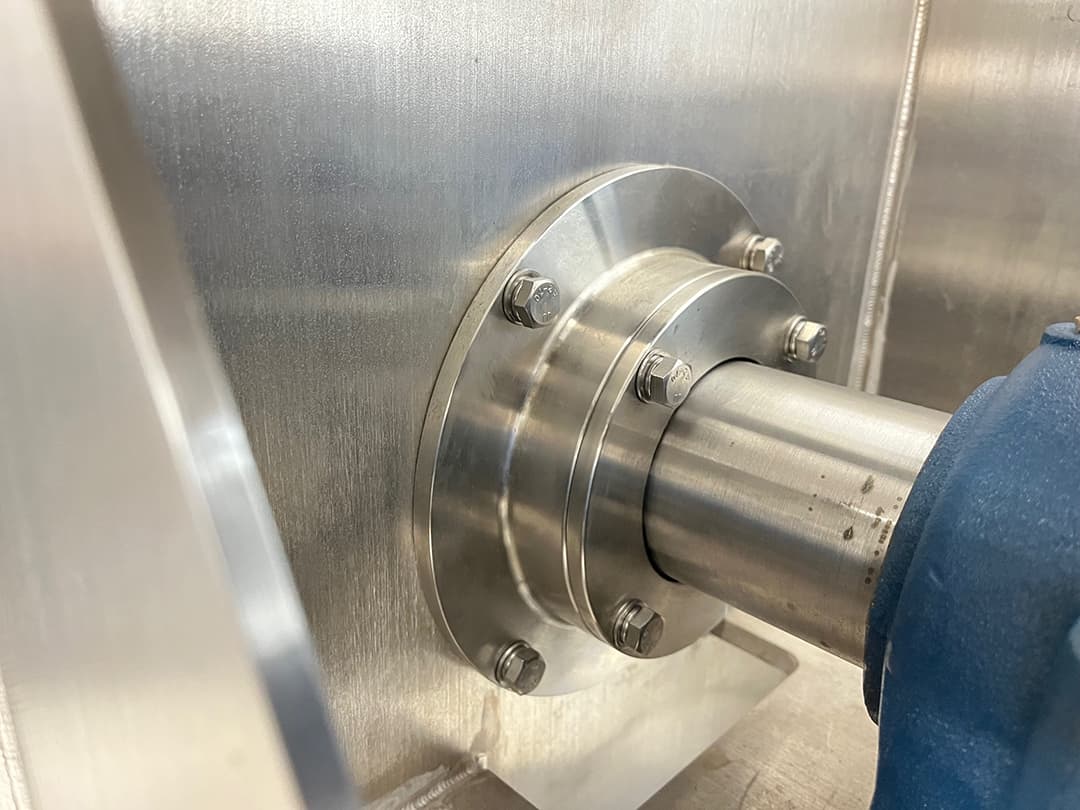

- Standard packing shaft sealing thus avoiding any type of contamination

- Blending area comes with hinged cover

- Operator safety grid in stainless steel with safety sensor standard

- Butterfly valve for product discharge at bottom centre

- Complete stainless steel construction (no paint)

- Direct drive heavy duty helicoil drive system

- All welds ground smooth for high quality uniform finish

- Power: 220, 3 phase, 50/60 Hz. is most common (other voltage available upon request)

- Mixing Capacity (kg/lbs): 175/350, 250/500, 400/800, 700/1400, 1060/2120, 1400/2800

- Mixing Capacity (liter): 200, 300, 500, 1000, 1500, 2000

- Horsepower: 5, 7.5, 10, 15, 20, 30

- Power: 220 VAC & 550 VAC

Overhead view of Ribbon Blender cover with ingredient door.

Ribbon Blender cover with gas shock lift cylinder.

Ribbon Blender pneumatic product discharge valve.

Ribbon Blender PTFE FDA approved shaft seal.

“Mike and the team helped us choose a dry filling system. They spent time with us and demonstrated the machine using a number of products we brought to their site.”

Neil Horner

Neil Horner

“As a contract manufacturer and co-packer we are doing business with JDA for more than 15 years for machinery, parts and repairs. They are great team, professional, knowledgeable and helpful. ”

Iman Navab

Iman Navab

“Far better quality than what we were expecting. Great value for the money. The most important feature that I hadn't considered was the after delivery service.”

Jeff Gamble

Jeff Gamble

“Knowledgeable people to deal with. Top notch service and after purchase care. Amazing experience overall.”

Derek Gravelle

Derek Gravelle

“Great Canadian company to work with. Our plant is full of their equipment, and it works. We have a JDA-1 labeller on our bottling line that's been going for 14 years!”

T. Grant

T. Grant

“I am 40 years in my industry and have purchased a lot of equipment. JDA get my full recommendation. You can count on the company and their equiptment.”

Ted Kasnetsis

Ted Kasnetsis

Why choose JDA Progress for your business?

In-stock

In-stock packaging equipment and parts for fast delivery.

Warranty

Receive a 1 year warranty on all machines and parts.

Value

Competitive pricing and expertise in choosing packaging solutions.

Support

Excellent after sales support for all packaging machines.